- HALFTONES WITH SEPARATION STUDIO HOW TO

- HALFTONES WITH SEPARATION STUDIO GENERATOR

- HALFTONES WITH SEPARATION STUDIO SOFTWARE

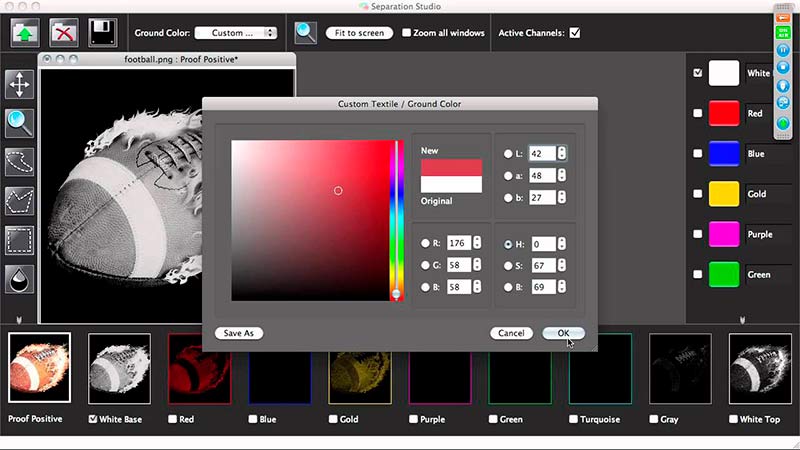

Just Open your image file with Separation Studio, and it will do the rest.

HALFTONES WITH SEPARATION STUDIO SOFTWARE

You don't need any other software to separate your graphics colors. Separation Studio is a color separation tool with Single Color and CMYK color separation type. The separations can be based on shapes defined in the application. Separation Studio is an application that allows you to create single color and cmyk half-tone patterns in vector- based formats.

HALFTONES WITH SEPARATION STUDIO GENERATOR

Separation Studio is powerful, easy to use color separation and artwork generator tool designed exclusively for Mac. Prepare your artworks like T-Shirt for production and printing. When you do, you will be rewarded with offering a wider variety of options to your customers, as well as with an opportunity to get more creating with the screen printed images you offer.Creative Artwork Designs are Made Easy. With some extra training and some practice, however, printing halftone images on textiles is certainly something you can master. Separating colors and printing halftones is certainly a specialized skill, even within the world of screen printing. However, reducers can cause inks to spread, leading to dot gain during printing that can ruin your final image. After all, you need the ink to travel through tiny, precise dots to reach your garment. It can be tempting to thin out your ink when printing halftone images. Avoid the temptation to use an ink reducer.Translucent inks generally offer a well-balanced color that blends well when printed to create the proper look for a process image. Translucent inks are preferred to high-opacity inks when printing halftone dots. Your mesh should be tensioned to a minimum of 35 Newtons per centimeter. A high-tension screen also is going to help the ink to sheer cleanly to make small, precise dots. Try a 70/90/70 triple-durometer squeegee. You need a sharp squeegee that will cleanly sheer the ink.

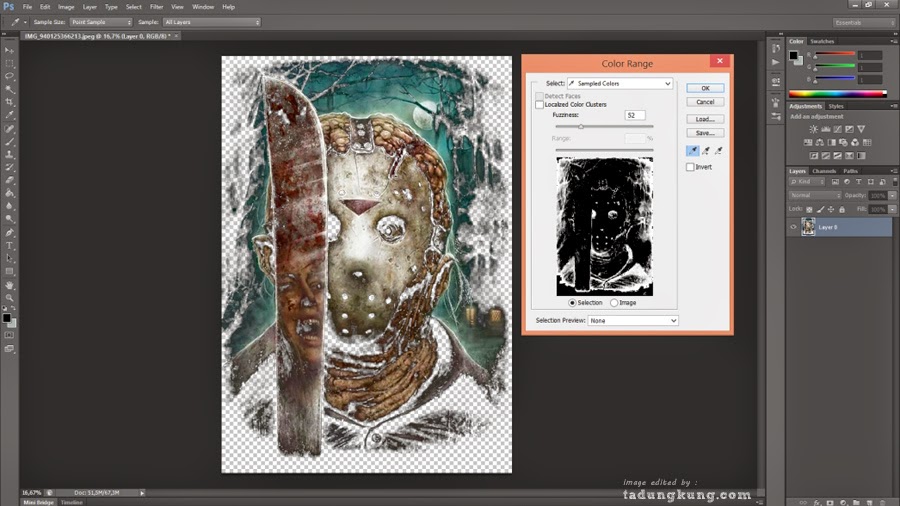

The squeegee you use for your average print job isn’t going to cut it when printing halftone images. When printing halftones, 230-count mesh is the most commonly used, though some printers prefer an even higher mesh count. To get those dots to print, you need a finer mesh. Obviously, all of your normal printing prep matters, like setting your off-contact distance and ensuring that all of your pallets and print heads are tight, but there are some other preparations to consider when printing halftone images: Once you’ve printed your films and exposed your screens, you’re ready to print your halftone image. Just set each individual layer to black, and print! Once you’ve separated out each layer and adjusted the settings, you’re just about ready to print your positives. Generally, when printing halftone dots, you’ll need to set the halftone to about a 45-line out and set the dot shape to elliptical. After you’ve selected your colors in your photo image, you’ll need to split the image into channels, which will produce a separate layer for each screen color. You’ll have to decide how many colors you’ll use and which colors you’ll need to reproduce your image. If you’re doing a simulated process print, in which you use a chosen variety of ink colors, this is trickier. If you’re doing a traditional CMYK process, the colors are a given - cyan, magenta, yellow and black.

HALFTONES WITH SEPARATION STUDIO HOW TO

You will have to figure out where those problems might occur and how to work around them before you begin printing. If you’re doing simulated process, certain colors (like purple and yellow) might appear muddy brown when mixed into a simulated process print. For example, red can overpower an image if you separate it out as it appears in the computer image. There might be tricks to the image that will play with your simple separation. Before you begin the color separation process, think about how the image will print.

0 kommentar(er)

0 kommentar(er)